Brazil Automotive Parts Zinc Die Casting Market

Brazil Automotive Parts Zinc Die Casting Market Size, Share, and COVID-19 Impact Analysis, By Production Process Type (Pressure Die Casting, Vacuum Die Casting, and Other Production Process Types), By Application Type (Body Assemblies, Engine Parts, Transmission Parts, and Other), Automotive Parts Zinc Die Casting Market Insights, Industry Trend, Forecasts to 2035

Report Overview

Table of Contents

Brazil Automotive Parts Zinc Die Casting Market Size Insights Forecasts to 2035

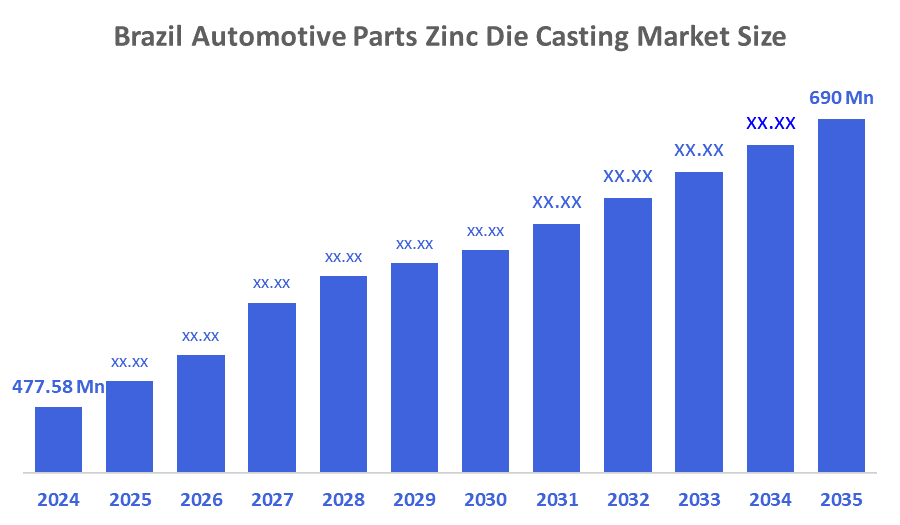

- The Brazil Automotive Parts Zinc Die Casting Market Size Was Estimated at USD 477.58 Million in 2024

- The Market Size is Expected to Grow at a CAGR of Around 3.4% from 2025 to 2035

- The Brazil Automotive Parts Zinc Die Casting Market Size is Expected to Reach USD 690 Million by 2035

According to a Research Report Published by Decisions Advisors & Consulting, The Brazil Automotive Parts Zinc Die Casting Market Size is anticipated to Reach USD 690 Million by 2035, Growing at a CAGR of 3.4% from 2025 to 2035. The Brazil automotive parts zinc die casting market is driven by increasing demand for lightweight, durable components, rising automotive production, stringent emission regulations, cost-effective manufacturing, growing use in electric vehicles, and the need for high-precision, corrosion-resistant parts.

Market Overview

Automotive parts zinc die casting is a manufacturing process where molten zinc is injected into precision molds to produce complex, high-strength, and corrosion-resistant components for vehicles. This technique enables mass production of lightweight parts with excellent dimensional accuracy, surface finish, and durability, commonly used in engines, transmissions, chassis, and electronic automotive assemblies. Furthermore, the market is growing due to increasing automotive production, rising demand for lightweight and corrosion-resistant components, expansion of electric vehicles, adoption of advanced zinc alloys, technological improvements in die casting, and cost-effective, high-precision manufacturing.

Technological advances in die-casting techniques, such as improved mold designs, automated systems, and better alloys, are increasing the efficiency and precision of zinc die-casting. These innovations enable manufacturers to create higher-quality components with less waste, shorter production schedules, and lower prices, hence increasing competitiveness in the automobile sector.

The Brazilian government is actively investing in industrial innovation, promoting advanced manufacturing technologies and modernization. In 2022, the Brazilian Development Bank (BNDES) increased financing for innovative industrial technology by 34.5%. Additionally, the Ministry of Industry and Trade reported that 43.7% of new industrial investments focus on improving production processes, with zinc die-casting technology receiving particular emphasis.

Report Coverage

This research report categorizes the market for the Brazil automotive parts zinc die casting market based on various segments and regions, and forecasts revenue growth and analyses trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Brazil automotive parts zinc die casting market. Recent market developments and competitive strategies, such as expansion, product launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Brazil automotive parts zinc die casting market.

Driving Factors

The Brazil automotive parts zinc die casting market is primarily driven by the growing automotive production and increasing demand for lightweight, durable, and corrosion-resistant components. Rising adoption of electric vehicles is further boosting demand, as manufacturers seek high-precision, efficient parts to enhance performance. Technological advancements in die casting processes and the use of advanced zinc alloys are enabling cost-effective, high-quality production. Additionally, supportive government initiatives promoting industrial innovation and modernization are encouraging investments in zinc die-casting technology, further fueling market growth.

Restraining Factors

The Brazil automotive parts zinc die casting market faces restraints from high raw material costs, especially zinc price fluctuations, and the availability of cheaper alternative materials like aluminum and plastics. Additionally, the complexity of die-casting processes, significant initial investment in machinery, and stringent environmental regulations can hinder small manufacturers, limiting market expansion despite growing automotive demand.

Market Segmentation

The Brazil automotive parts zinc die casting market share is classified into production process type and application type.

- The pressure die casting segment accounted for the largest revenue market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Brazil automotive parts zinc die casting market is segmented by production process type into pressure die casting, vacuum die casting, and other production process types. Among these, the pressure die casting segment accounted for the largest revenue market share in 2024 and is expected to grow at a significant CAGR during the forecast period. Pressure die casting dominates because it enables high-volume production of complex, precision components with excellent dimensional accuracy and smooth surface finishes. It reduces material waste and production time compared to other methods, lowering overall manufacturing costs. The process is highly suitable for producing lightweight, durable, and corrosion-resistant automotive parts required in engines, transmissions, and chassis. Additionally, its compatibility with advanced zinc alloys and modern automation technologies makes it the preferred choice for automotive manufacturers seeking efficiency and quality.

- The engine parts segment accounted for the largest revenue share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Brazil automotive parts zinc die casting market is segmented by application type into body assemblies, engine parts, transmission parts, and other. Among these, the engine parts segment accounted for the largest revenue share in 2024 and is expected to grow at a significant CAGR during the forecast period. Engine parts dominate because they require high strength, dimensional accuracy, and resistance to wear and corrosion, which zinc die casting provides efficiently. The process allows the production of complex shapes with tight tolerances, essential for engine components such as housings, brackets, and valve parts. Additionally, increasing automotive production, rising demand for lightweight and durable engine components, and the growing adoption of advanced zinc alloys make this application the most significant contributor to market growth.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Brazil automotive parts zinc die casting market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborate analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Sandhar Technologies Ltd

- Brillcast Manufacturing LLC

- Dynacast

- Pace Industries

- Ashok Minda Group

- Empire Casting Co

- Kemlows Diecasting Products Ltd

- Ningbo Die Casting Company

- Cascade Die Casting Group Inc

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments:

In March 2025, Dynacast International (USA) launched a new range of zinc alloys with improved corrosion and thermal conductivity for EV battery parts, designed to address growing demand for precision die-cast components in electric vehicles and consolidate its position as a supplier of choice to international automakers.

Market Segment

This study forecasts revenue at the Brazil, regional, and country levels from 2020 to 2035. Decisions Advisors has segmented the Brazil automotive parts zinc die casting market based on the below-mentioned segments:

Brazil Automotive Parts Zinc Die Casting Market, By Production Process Type

- Pressure Die Casting

- Vacuum Die Casting

- Other Production Process Types

Brazil Automotive Parts Zinc Die Casting Market, By Application Type

- Body Assemblies

- Engine Parts

- Transmission Parts

- Other

FAQ’s

Q1: What is zinc die casting in automotive parts?

Zinc die casting is a manufacturing process where molten zinc is injected into molds to produce high-precision, durable, and corrosion-resistant automotive components.

Q2: Which automotive components commonly use zinc die casting?

Engine parts, transmission parts, body assemblies, brackets, housings, and electronic component enclosures commonly use zinc die casting.

Q3: What drives the growth of the zinc die casting market in Brazil?

Market growth is driven by rising automotive production, demand for lightweight durable parts, electric vehicle adoption, and technological advancements in die casting.

Q4: What are the main challenges in this market?

High raw material costs, complex manufacturing processes, initial investment requirements, and environmental regulations can restrain market growth.

Q5: Which production process dominates in Brazil?

Pressure die casting dominates due to its efficiency in producing complex, high-precision components at scale.

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Country |

| Pages | 186 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Jan 2026 |

| Access | Download from this page |