Drone Bearing Market

Global Drone Bearing Market Size, Share, and COVID-19 Impact Analysis, Impact of Tariff and Trade War Analysis, By Bearing Type (Ball Bearings, Roller Bearings, Ceramic Bearings, and Magnetic Bearings), By Application (Motors, Gimbals, Propellers, Landing Gear, and Payload Systems), and By Region (Asia Pacific, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025-2035.

Report Overview

Table of Contents

Drone Bearing Market Summary, Size & Emerging Trends

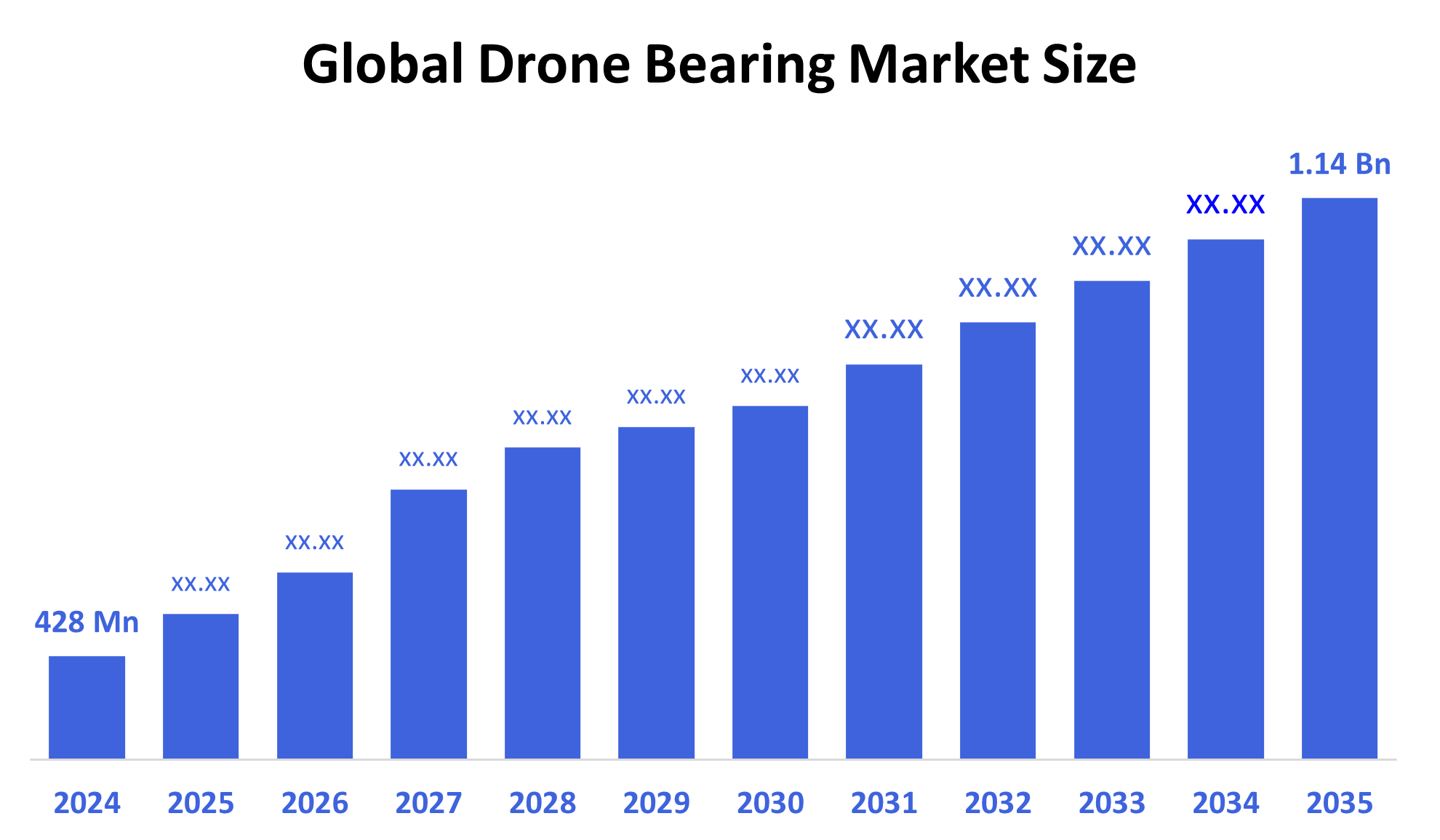

- According to Spherical Insights, The Global Drone Bearing Market Size is Expected To Grow From USD 428 Million in 2024 to USD 1.14 Billion by 2035, at a CAGR of 9.6% during the Forecast Period 2025-2035.

- The key growth drivers include the increasing deployment of drones across commercial and industrial sectors, rising demand for precision components in UAV motors and gimbals, and the push towards miniaturization and high-performance bearings capable of withstanding high RPMs and vibrations.

Key Market Insights

- Asia Pacific is expected to account for the largest share in the drone bearing market during the forecast period.

- Among bearing types, ball bearings dominate due to their ubiquity in drone motors and propeller assemblies.

- In applications, motors and camera gimbals are likely the largest segments owing to their critical performance requirements.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 428 million

- 2035 Projected Market Size: USD 1.14 Billion

- CAGR (2025-2035): 9.6%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Drone Bearing Market

The drone bearing market centers on the production of specialized bearings used in unmanned aerial vehicles (UAVs), enabling efficient and stable operation of motors, gimbals, and propellers. These bearings are designed to withstand high-speed rotations, vibrations, and varying environmental conditions, making them critical to drone performance. Widely used in consumer, commercial, and military drones, these bearings enhance durability, reduce friction, and ensure precise motion control. Government investments in drone infrastructure, growing use in logistics and surveillance, and advancements in miniaturized mechanical components are key factors supporting the drone bearing market. With the expansion of drone applications in delivery, agriculture, inspection, and defense, the market is positioned for robust growth, reinforcing its importance within the broader UAV ecosystem.

Drone Bearing Market Trends

- There’s a growing push for lightweight and heat-resistant bearing materials such as ceramics to improve drone endurance and efficiency.

- High-RPM precision ball bearings are increasingly adopted in compact drones for smoother and longer flight.

- Companies are collaborating with drone manufacturers to develop customized bearing solutions for specific drone applications and environments.

Drone Bearing Market Dynamics

Driving Factors: The surge in drone adoption across diverse sectors like agriculture

The surge in drone adoption across diverse sectors like agriculture, defense, logistics, and infrastructure inspection is a major catalyst for the drone bearing market. In agriculture, drones are used for crop monitoring, spraying, and precision farming, demanding reliable and efficient mechanical parts like bearings to ensure smooth operation in varying environments. Defense applications require high-performance drones for surveillance and reconnaissance, where durability and precision are critical. The logistics industry increasingly relies on drones for last-mile delivery, pushing demand for lightweight and energy-efficient components to extend flight times and payload capacity. Additionally, infrastructure inspection such as power lines, pipelines, and bridges require drones equipped with sophisticated motion systems relying on specialized bearings to provide stability and accuracy.

Restrain Factors: Manufacturing miniature bearings to aerospace-grade precision is complex

One of the limiting factors for the drone bearing market is the emergence of alternative motor technologies that reduce or eliminate the need for traditional bearings. For example, some brushless direct-drive motors and magnetic levitation systems may require fewer mechanical bearings, impacting overall demand. The volatility in raw material prices, especially for specialty steel and ceramic powders, can increase production costs, squeezing margins for bearing manufacturers. Manufacturing miniature bearings to aerospace-grade precision is complex and costly, requiring stringent quality controls and sophisticated machinery. This complexity can limit the number of manufacturers capable of meeting demand, restricting supply.

Opportunity: Innovations in drone design are creating significant opportunities

Innovations in drone design are creating significant opportunities for bearing manufacturers to offer custom-engineered solutions tailored to specific drone models and use-cases. For instance, ceramic bearings offer lower weight and better heat tolerance, making them attractive for high-end drones requiring longer flight times and more reliable performance in extreme environments. The ongoing electrification trend, combined with hybrid propulsion systems, opens pathways for advanced magnetic bearings that reduce mechanical contact, lowering wear and maintenance needs. These technological advances promise to enhance drone efficiency and durability, driving bearing demand.

Challenges: Drone industry suffers from a lack of standardized bearing specifications

Advanced bearing materials such as ceramics are expensive and require intricate manufacturing processes, which can be a barrier for smaller companies or new entrants looking to compete. Achieving consistent quality and meeting the strict tolerances demanded by drone manufacturers also raises operational costs. Moreover, the drone industry suffers from a lack of standardized bearing specifications due to diverse drone designs and applications. This inconsistency complicates the supply chain, as bearing suppliers must tailor products to varying requirements, increasing complexity and reducing economies of scale.

Global Drone Bearing Market Ecosystem Analysis

The global drone bearing market ecosystem includes component suppliers (specialized bearing manufacturers), drone OEMs, system integrators, and end-users across commercial and military sectors. Key players like SKF, NSK, and Timken dominate the high-precision bearing segment. Drone manufacturers rely on long-term contracts with bearing producers to ensure quality and consistency. Regulatory authorities such as the FAA and EASA influence component compliance and safety standards. The ecosystem’s expansion is driven by innovations in lightweight materials, increased R&D investments, and strategic alliances between drone and bearing manufacturers.

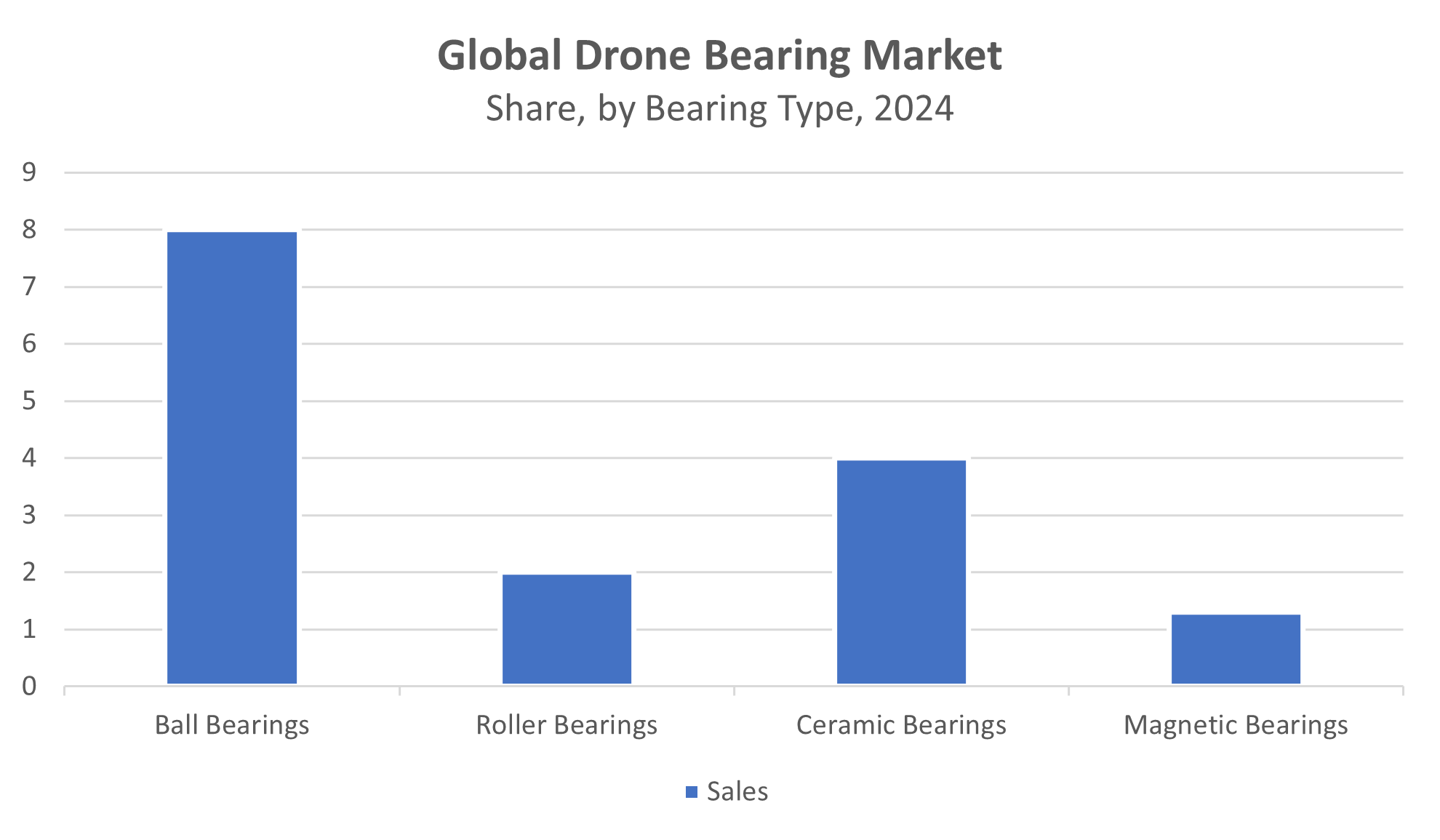

Global Drone Bearing Market, By Bearing Type

The ball bearings segment dominated the drone bearing market in terms of revenue during the forecast period, accounting for approximately 55% of the total market share. This dominance is primarily due to ball bearings’ versatile performance, reliability, and ability to handle both radial and axial loads efficiently, which are critical requirements in drone applications. Ball bearings offer smooth rotational motion with minimal friction, enhancing drone motor efficiency and extending flight duration. Their relatively simple design and widespread availability make them cost-effective compared to other bearing types, contributing to their widespread adoption in commercial and industrial drones.

The ceramic bearings segment accounted for the fastest growth rate during the forecast period, with a CAGR of approximately 9.8%, reflecting its rising adoption in the drone bearing market. Ceramic bearings offer significant advantages such as lower weight, higher heat resistance, and reduced friction, which directly contribute to longer drone flight times and enhanced performance. Their non-magnetic nature and corrosion resistance make them particularly suitable for drones operating in harsh environments or specialized applications like defense and aerospace.

Global Drone Bearing Market, By Application

The motor segment accounted for the largest revenue share of approximately 46% in the global drone bearing market. This significant share is attributed to the critical role that bearings play in drone motors, which are the core components responsible for propelling and maneuvering drones. Bearings used in drone motors must provide high precision, durability, and low friction to ensure efficient power transmission and smooth rotation of the motor shafts. Given that drone motors operate at high speeds and under varying load conditions, the demand for reliable, high-performance bearings in this segment remains consistently strong.

The gimbal segment accounted for a significant revenue share of approximately 28% in the global drone bearing market. Gimbals are critical components that stabilize cameras and sensors on drones, enabling smooth and precise footage even during rapid drone movements or adverse weather conditions. Bearings used in gimbals must offer high precision, low friction, and excellent durability to allow for seamless multi-axis rotation and vibration dampening. The growing demand for high-quality aerial photography, videography, and surveillance applications is driving the need for advanced gimbal systems equipped with reliable bearings.

Asia Pacific is expected to account for the largest share of the global drone bearing market during the forecast period, holding approximately 43% of the total market revenue. This dominance is driven by the presence of strong drone manufacturing hubs in countries such as China, Japan, and India, which benefit from advanced industrial infrastructure and skilled labor. Government support through favorable policies, funding, and regulatory frameworks further accelerates market growth by promoting research, innovation, and commercial deployment of drones.

India is experiencing significant growth in the drone bearing market, with a projected CAGR of approximately 12.4% during the forecast period, driven by the rapid expansion of its drone startup ecosystem, increased defense procurement, and the government’s “Make in India” initiative. Key industrial clusters in Maharashtra, Telangana, and Tamil Nadu are actively investing in drone manufacturing capabilities, further strengthening the country’s position in this market.

North America is also anticipated to register a significant CAGR, holding around 25% of the global market share, fueled primarily by substantial defense investments, infrastructure monitoring projects, and the growing use of drones in logistics. The region benefits from advanced aerospace-grade bearing materials and stringent quality standards that support the demand for premium drone bearings.

WORLDWIDE TOP KEY PLAYERS IN THE DRONE BEARING MARKET INCLUDE

- SKF Group

- NSK Ltd.

- NTN Corporation

- Timken Company

- Schaeffler AG

- National Engineering Industries Ltd. (NBC Bearings)

- JTEKT Corporation

- Aurora Bearing Company

- GRW Bearings

- C&U Group

- Others

Product Launches in Drone Bearing Market

- In June 2024, SKF Group introduced a new line of miniature ceramic ball bearings specifically engineered for high-RPM drone motors. These bearings aim to improve energy efficiency and reduce wear during prolonged flights.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the drone bearing market based on the below-mentioned segments:

Global Drone Bearing Market, By Bearing Type

- Ball Bearings

- Roller Bearings

- Ceramic Bearings

- Magnetic Bearings

Global Drone Bearing Market, By Application

- Motors

- Propellers

- Gimbals

- Landing Gear

- Payload Systems

Global Drone Bearing Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

FAQs

Q: Which bearing type is expected to grow the fastest?

A: Ceramic bearings are expected to grow the fastest, with a CAGR of approximately 9.8%, driven by demand for lightweight, heat-resistant, and corrosion-resistant materials.

Q: Which application segment holds the largest revenue share in the drone bearing market?

A: The motor segment holds the largest share, approximately 46%, as bearings in motors are critical for drone propulsion and maneuvering.

Q: What is the significance of the gimbal segment in the drone bearing market?

A: The gimbal segment accounts for about 28% of the market, reflecting the high demand for precise stabilization of cameras and sensors in drones for photography, videography, and surveillance.

Q: Who are the key players in the Global Drone Bearing Market?

A: Leading companies include SKF Group, NSK Ltd., NTN Corporation, Timken Company, Schaeffler AG, National Engineering Industries Ltd., JTEKT Corporation, Aurora Bearing Company, GRW Bearings, and C&U Group.

Q: What are the main drivers for growth in the drone bearing market?

A: Growth is driven by increased drone deployment in agriculture, defense, logistics, and infrastructure inspection, rising demand for precision components, and advancements in miniaturization and high-performance materials.

Q: What challenges are impacting the drone bearing market?

A: Challenges include the complexity and cost of manufacturing miniature aerospace-grade bearings, volatility in raw material prices, lack of standardized bearing specifications across diverse drone designs, and competition from alternative motor technologies.

Q: What opportunities exist for innovation in the drone bearing market?

A: Opportunities arise from developing custom-engineered bearing solutions, adoption of ceramic and magnetic bearings, and advances in lightweight, heat-resistant materials that enhance drone endurance and efficiency.

Q: What recent product launches have occurred in the drone bearing market?

A: In June 2024, SKF Group launched a new line of miniature ceramic ball bearings designed for high-RPM drone motors, aimed at improving energy efficiency and reducing wear during prolonged flights.

Q: How does India contribute to the drone bearing market?

A: India is experiencing rapid growth with a projected CAGR of 12.4%, driven by a growing drone startup ecosystem, increased defense procurement, and government initiatives like “Make in India.”

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Global |

| Pages | 200 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Sep 2025 |

| Access | Download from this page |