Global Failure Analysis Test Equipment Market

Global Failure Analysis Test Equipment Market Size, Share, and COVID-19 Impact Analysis, By Product (Scanning Electron Microscope (SEM), Transmission Electron Microscope (TEM), Focused Ion Beam System, Dual Beam System, Others), By Technology (Energy Dispersive X-Ray Spectroscopy (EDX), Secondary Ion Mass Spectroscopy (SIMS), Focused Ion Beam (FIB), Broad Ion Miling (BIM), Relative Ion Etching (RIE), Scanning Probe Microscope (SPM), Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025-2035.

Report Overview

Table of Contents

Failure Analysis Test Equipment Market Summary

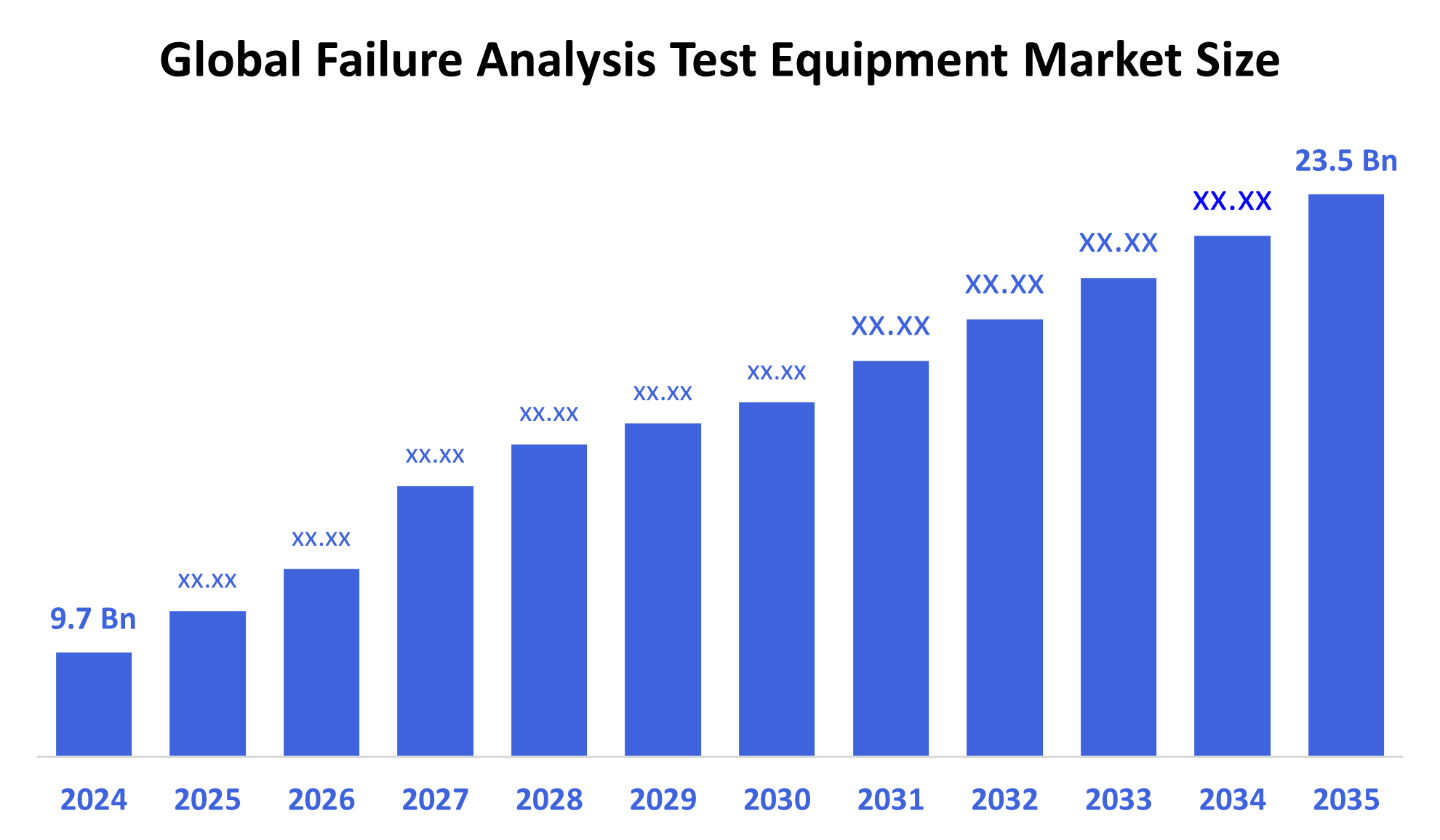

- The Global Failure Analysis Test Equipment Market Size Was Estimated at USD 9.7 Billion in 2024 and is Projected to Reach USD 23.5 Billion by 2035, Growing at a CAGR of 8.38% from 2025 to 2035.

- The market for failure analysis test equipment is growing as a result of increased demand for dependable, highperformance electronics and semiconductors, tighter quality control regulations, developments in intricate chip architectures and nanotechnology, and the growing use of automation and artifici al intelligence (AI) to improve accuracy and lower costs.

Key Regional and Segment-Wise Insights

- In 2024, the Asia Pacific region held the largest revenue share of over 32.6% and dominated the market globally.

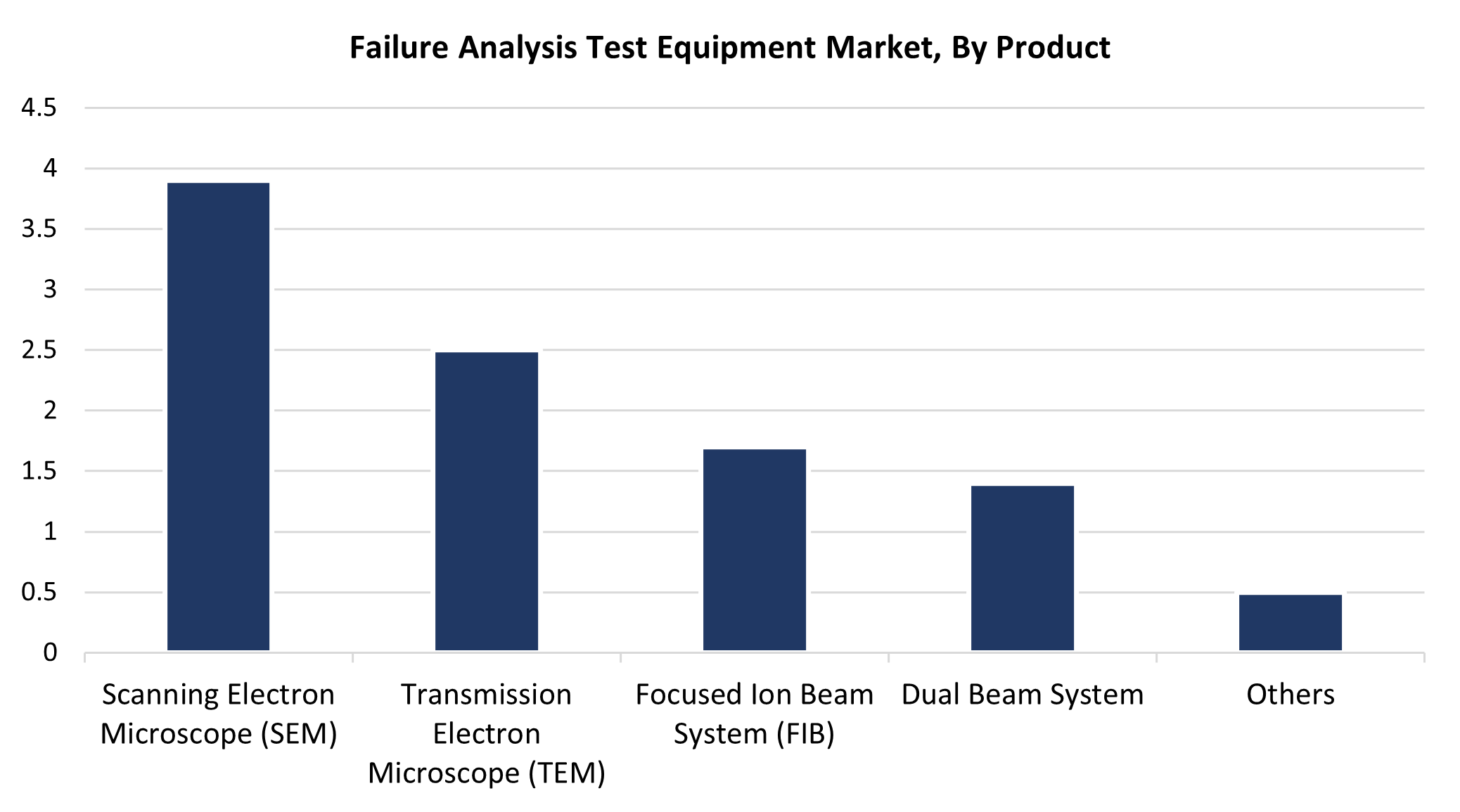

- In 2024, the Scanning Electron Microscope (SEM) segment had the highest market share by product, accounting for 39.4%.

- In 2024, the Energy Dispersive X-Ray Spectroscopy (EDX) segment had the biggest market share by technology, accounting for 28.7%.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 9.7 Billion

- 2035 Projected Market Size: USD 23.5 Billion

- CAGR (2025-2035): 8.38%

- Asia Pacific: Largest market in 2024

The failure analysis test equipment market serves as a platform for diagnostic tools that identify and assess electronic device defects and material failures. The vital equipment for ensuring product quality and reliability across electronics, automotive manufacturing, and aerospace industries comprises spectrometers together with electron analyzers, thermal imaging equipment, and microscopes. The market expands because advanced materials see rising use and electronic components become more intricate, while consumers demand durable products of superior quality. Most manufacturers must dedicate substantial funds toward failure analysis because quality standards and regulations demand it, while they need to reduce product recalls and enhance safety, along with increasing customer satisfaction.

The failure analysis test equipment market experiences strong changes because of new technologies, including automatic inspection devices and AI-powered defect detection systems, as well as advanced imaging systems that improve precision and boost productivity. The combination of machine learning with data analytics enables faster completion of predictive maintenance and root cause analysis tasks. The worldwide expansion of this market receives support from government regulations, which enforce environmental compliance together with quality control measures and product safety standards. Research and development support for materials science and electronics, along with other initiatives, drives market growth because businesses need to uphold standards while avoiding high-cost failures.

Product Insights

Why Did the Scanning Electron Microscope (SEM) Segment Lead the Failure Analysis Test Equipment Market with a 39.4% Revenue Share in 2024?

In 2024, the Scanning Electron Microscope (SEM) segment led the failure analysis test equipment market with the largest revenue share of 39.4%. The high-resolution imaging capabilities of SEM, which enable in-depth examination of the surface morphology, content, and microstructural characteristics of materials and components, are responsible for this supremacy. SEM receives widespread adoption across industries such as automotive, aerospace, materials research, and electronics for precise failure diagnosis and quality control purposes. The fundamental ability of the tool to perform elemental analysis and generate three-dimensional images makes it essential for detecting defects and understanding failure patterns. The continuous enhancement of SEM technology through improved resolution, faster imaging, and automated capabilities boosts its applications, which drives market demand, thus maintaining its position as the top failure analysis equipment in the industry.

The Transmission Electron Microscope (TEM) segment within the failure analysis test equipment market is predicted to experience a substantial CAGR during the forecast period. The growth of this segment occurs because TEM delivers extremely detailed imaging capabilities alongside atomic-level structural examination, which scientists use to understand cutting edge materials and semiconductors. The growing requirement for precise failure analysis in the electronic and nanotechnology, and biotechnology sectors drives the adoption of TEM. Modern technological advancements, including enhanced imaging approaches and automated processes, help increase both the capabilities and user-friendliness of TEM equipment. The failure analysis test equipment market experiences growth because of TEM, which gains momentum through rising research funding and increased focus on ensuring product dependability.

Technology Insights

What Factors Enabled the Energy Dispersive X-Ray Spectroscopy (EDX) Segment to Capture the Largest Revenue Share of 28.7% in the Failure Analysis Test Equipment Market in 2024?

The Energy Dispersive X-Ray Spectroscopy (EDX) segment of the failure analysis test equipment market held the highest revenue share of 28.7% in 2024. The extensive application of EDX technology for elemental analysis and chemical characterization makes it essential for material composition determination and impurity detection across multiple sectors, including materials science, electronics, aerospace, and automotive. The performance of EDX reaches higher levels because it connects with SEM microscopes, which produce exact compositional readings together with precise real-time imagery. EDX technology adoption continues to grow because companies need exact failure detection along with quality control and advanced materials research capabilities. The market position of EDX strengthens through continuous advancements, which boost sensitivity as well as speed and automation, thus making it the leading technology segment for failure analysis testing.

The Scanning Probe Microscope (SPM) segment of the failure analysis test equipment market will experience a considerable CAGR throughout the forecast period. The growth of SPM stems from its capability to deliver precise nanoscale surface characterization for studying material properties and mechanical behaviors, and surface topography. The SPM instrument is gaining heightened importance for detailed failure assessments together with quality inspections in semiconductor production and materials science applications, and nanotechnology research. The development of SPM technology includes enhanced imaging modes together with automation and instrument interface capabilities, which improve both precision and user-friendliness. The increasing adoption of the SPM stems from both rising research and development costs and the expanding requirement for precise testing in innovative applications, thus establishing itself as a crucial growth sector within the failure analysis test market.

Regional Insights

The North American failure analysis test equipment market is projected to grow significantly during the forecast period. The expansion of this market results from the strong industrial base that includes electronics and aircraft manufacturing, automotive production, and semiconductor fabrication facilities, which need advanced failure analysis tools to maintain product quality and reliability. The market experiences growth because of enhanced research and development funding, together with rising performance and safety standards. Modern technical advancements, along with AI-powered automated testing equipment, have enhanced failure detection capabilities. The projected market expansion in North America between 2022 and 2027 is driven by governmental initiatives supporting manufacturing quality and innovation.

Asia Pacific Failure Analysis Test Equipment Market Trends

The Asia Pacific region led the failure analysis test equipment market with the largest revenue share of 32.6% in 2024. The primary factors behind this regional dominance stem from fast industrial growth, along with expanding electronic and semiconductor production centers and rising research and development expenses in China, Japan, South Korea, and India. Advanced failure analysis tools become essential because product quality and reliability need protection in the region's expanding automotive and aerospace, and materials science markets. The expansion of the market receives support through government initiatives that advance innovation while enhancing industrial standards and backing intelligent manufacturing systems. Asia Pacific stands as a key force in the worldwide failure analysis test equipment market because it provides affordable manufacturing and testing solutions that attract significant worldwide adoption.

Europe Failure Analysis Test Equipment Market Trends

The European market for failure analysis test equipment experiences significant growth due to its well-established manufacturing base, which serves electronics and automotive as well as aerospace industries. The region's strict product safety requirements, together with high standards for reliability, drive the need for advanced failure analysis instruments. The market experiences growth due to increased investment in research and development, particularly within material science and nanotechnology sectors. The adoption of automated testing equipment with artificial intelligence capabilities boosts industry utilization because these technologies enhance analysis speed and precision. The market grows through government initiatives that support innovation and sustainable production methods, and intelligent manufacturing systems. The European market shows continuous strong growth because of its developed industrial facilities and growing focus on product quality standards.

Key Failure Analysis Test Equipment Companies:

The following are the leading companies in the failure analysis test equipment market. These companies collectively hold the largest market share and dictate industry trends.

- Thermo Fisher Scientific Inc.

- Veeco Instruments

- Hitachi High-Technologies Corporation

- CARL Zeiss SMT GmbH

- Motion X Corp.

- Oxford Instruments

- Stress Engineering Services, Inc

- Bruker

- Tescan Orsay Holding

- Leica Microsystems

- A&D Company Ltd.

- Jeol Ltd.

- HORIBA, Ltd.

- Imina Technologies SA.

- Rigaku Corporation

- Others

Recent Developments

- In July 2025, Thermo Fisher declared the release of its electron microscopes, the Scios 3 and Talos 12. These cutting-edge instruments are intended to improve materials analysis and high-resolution imaging, assisting with research, failure analysis, and nanotechnology applications.

- In January 2024, the AP-380 family of analyzers was introduced by HORIBA, Ltd. to meet a variety of Focused Ion Beam (FIB) quality monitoring requirements. Beyond the regulatory applications of the AP-370 series, the AP-380 series expands its reach to serve a wider range of sectors thanks to its globally optimized software and flexible, environmentally friendly design.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the failure analysis test equipment market based on the below-mentioned segments:

Global Failure Analysis Test Equipment Market, By Product

- Scanning Electron Microscope (SEM)

- Transmission Electron Microscope (TEM)

- Focused Ion Beam System (FIB)

- Dual Beam System

- Others

Global Failure Analysis Test Equipment Market, By Technology

- Energy Dispersive X-Ray Spectroscopy (EDX)

- Secondary Ion Mass Spectroscopy (SIMS)

- Focused Ion Beam (FIB)

- Broad Ion Miling (BIM)

- Relative Ion Etching (RIE)

- Scanning Probe Microscope (SPM)

- Others

Global Failure Analysis Test Equipment Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Global |

| Pages | 210 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Sep 2025 |

| Access | Download from this page |