Japan Vertical Storage Tank Market

Japan Vertical Storage Tank Market Size, Share, and COVID-19 Impact Analysis, By Material Type (Steel, Concrete, Polyethylene, and Others), By Application (Oil & Gas, Chemical Processing, Water & Wastewater, and Food & Beverage), and Japan Vertical Storage Tank Market Insights, Industry Trend, Forecasts to 2035

Report Overview

Table of Contents

Japan Vertical Storage Tank Market Insights Forecasts to 2035

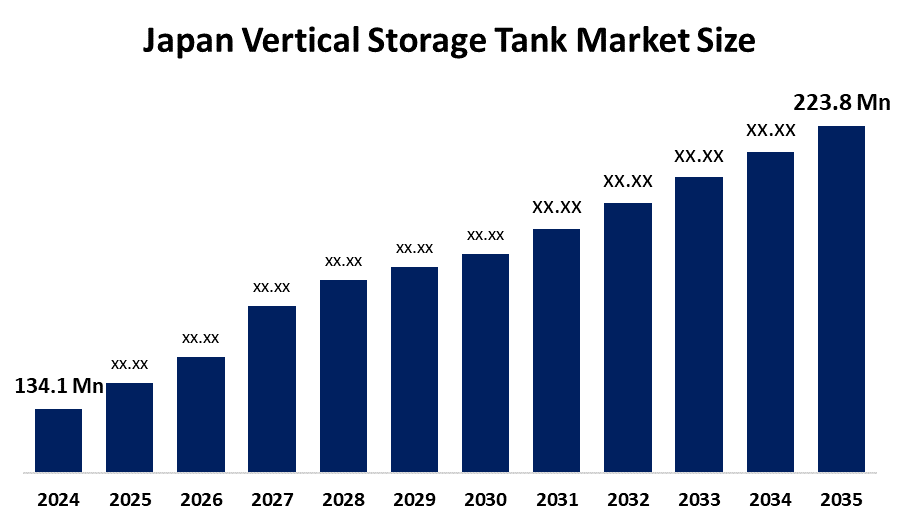

• The Japan Vertical Storage Tank Market Size Was Estimated at USD 134.1 Million in 2024

• The Market Size is Expected to Grow at a CAGR of Around 4.77% from 2025 to 2035

• The Japan Vertical Storage Tank Market Size is Expected to Reach USD 223.8 Million by 2035

According to a research report published by Decision Advisor & Consulting, the Japan Vertical Storage Tank Market size is anticipated to reach USD 223.8 Million by 2035, growing at a CAGR of 4.77% from 2025 to 2035. The market is driven by industrial infrastructure modernisation, rising demand for safe liquid and chemical storage, and the shift towards corrosion-resistant and high-strength tank materials. The country’s environmental safety regulations and energy policy reforms also strengthen the need for secure, durable, and compliant vertical storage systems.

Market Overview

The Japan vertical storage tank refers to a cylindrical upright vessel designed for storing liquids such as fuel, chemicals, water, and industrial fluids. These tanks require minimal land area and are widely used in oil & gas, chemicals, water treatment, and food processing industries. Japan’s vertical storage tank market growth is supported by the country’s expanding chemical production capacity, modernization of refineries, growing LNG terminal activities, and rising demand for high-performance tank systems. The industries in Japan increasingly require tanks with high corrosion resistance, enhanced durability, and advanced monitoring capabilities for leak detection and temperature control. The demand is further fueled by Japan’s national initiatives to strengthen industrial safety through updated fire protection norms, earthquake-resistant tank designs, and strict hazardous material storage compliance.

The Ministry of Economy, Trade and Industry (METI), the Japan Organization for Metals and Energy Security (JOGMEC), and the Green Innovation Fund provide regulatory and financial support to upgrade storage systems, increase energy efficiency, and promote sustainability in industrial storage infrastructure.

Report Coverage

This research report categorizes the market for the Japan vertical storage tank market based on various segments and regions, and forecasts revenue growth and analyses trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Japan vertical storage tank market. Recent market developments and competitive strategies, such as expansion, product launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Japan vertical storage tank market.

Driving Factors

The Japanese vertical storage tank market is driven by growing industrial upgrading activities, expansion of petrochemical and refinery operations, and increasing demand for safe and durable liquid storage structures. Advanced tank materials such as high-strength steel and polymer-lined tanks improve resistance against corrosion and extreme temperatures, which is important for chemical, LNG, and hazardous materials storage. Additionally, Japan’s focus on hydrogen, ammonia, and carbon-capture infrastructure increases the demand for vertically oriented tanks that can safely store pressurised or temperature-sensitive materials. The expansion of water and wastewater treatment facilities, along with Japan’s disaster preparedness programs, further strengthens adoption across public utility sectors.

Restraining Factors

The Japan vertical storage tank market is restrained by high fabrication and installation costs, especially for tanks requiring double-wall protection, seismic reinforcement, or advanced metal alloys. The strict regulatory requirements in Japan also increase compliance costs for manufacturers and end-users. Additionally, the shortage of skilled welders, high labor expenses, and long lead times for speciality steel materials limit the pace of tank construction projects.

Market Segmentation

The Japan vertical storage tank market share is categorised by Material Type and Application.

• The steel segment accounted for the largest revenue market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan vertical storage tank market is segmented by material type into steel, concrete, polyethylene, and others. Among these, the steel segment accounted for the largest revenue market share in 2024 and is expected to grow at a significant CAGR during the forecast period. The segmental growth is driven by steel’s superior structural strength, reliability, fire resistance, and suitability for high-pressure industrial liquids. Japan’s refinery modernisation, LNG terminal developments, and chemical manufacturing expansions further support steel tank demand, along with the rising adoption of corrosion-resistant steel alloys.

• The oil & gas segment dominated the market in 2024 and is projected to grow at a substantial CAGR during the forecast period.

The Japan vertical storage tank market is segmented by application into oil & gas, chemical processing, water & wastewater, and food & beverage. Among these, the oil & gas segment accounted for the largest revenue share in 2024 and is expected to grow at a significant CAGR during the forecast period. The segment growth is due to increasing petroleum storage needs, LNG expansion, refinery upgrades, and Japan’s long-term energy security programs. The demand for reliable storage systems is further enhanced by stricter safety regulations and the rising need for earthquake-resistant storage solutions.

Competitive Analysis

The report offers the appropriate analysis of the key organizations/companies involved within the Japan vertical storage tank market, along with a comparative evaluation primarily based on their product offerings, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborate analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Nippon Steel Engineering Co., Ltd.

- Toyo Kanetsu K.K. (TKK)

- JFE Engineering Corporation

- JFE Technos Co., Ltd.

- IHI Corporation

- Mitsubishi Heavy Industries, Ltd.

- ENEOS Corporation

- Cosmo Oil Co., Ltd.

- Kawasaki Heavy Industries, Ltd.

- JX Nippon Oil & Gas Exploration Corporation

- Other

Recent Developments

• In September 2024, Nippon Steel Engineering was selected by JOGMEC for an advanced CCS storage-infrastructure engineering project. The initiative includes the development of CO? storage tank systems and handling designs, supporting Japan’s efforts to expand safe and efficient carbon-capture and storage capabilities.

Market Segment

This study forecasts revenue at the Japan, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the Japan Vertical Storage Tank Market based on the below-mentioned segments:

Japan Vertical Storage Tank Market, By Material Type

• Steel

• Concrete

• Polyethylene

• Others

Japan Vertical Storage Tank Market, By Application

• Oil & Gas

• Chemical Processing

• Water & Wastewater

• Food & Beverage

FAQs

Q: What is the Japan vertical storage tank market size?

A: The Japan vertical storage tank market size is expected to grow from USD 0.92 Million in 2024 to USD 1.67 Million by 2035, growing at a CAGR of 5.6% during the forecast period 2025–2035.

Q: What are the key growth drivers of the market?

A: Market growth is driven by rising industrial automation, increasing demand for corrosion-resistant storage systems, and rising investments in chemical and energy infrastructure.

Q: What factors restrain the Japan vertical storage tank market?

A: The market is restrained by high installation costs, strict regulatory compliance requirements, and the financial burden of advanced material technologies.

Q: How is the market segmented by material type?

A: The market is segmented into steel, concrete, polyethylene, and others.

Q: Who are the key players in the Japan vertical storage tank market?

A: Key companies include Nippon Steel Engineering Co., Ltd., Toyo Engineering Corporation, JFE Engineering Corporation, Fujikin Incorporated, and CST Industries.

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Country |

| Pages | 240 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Dec 2025 |

| Access | Download from this page |