Global Polyetherketoneketone Filaments Market

Global Polyetherketoneketone Filaments Market Size, Share, and COVID-19 Impact Analysis, Impact of Tariff and Trade War Analysis, By Product (Carbon Fiber Reinforced PEKK Filament, Unfilled PEKK Filament, and Glass Fiber Reinforced PEKK Filament), By Application (Aerospace, Automotive, Medical Devices, and Industrial Components), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Report Overview

Table of Contents

Polyetherketoneketone Filaments Market Summary, Size & Emerging Trends

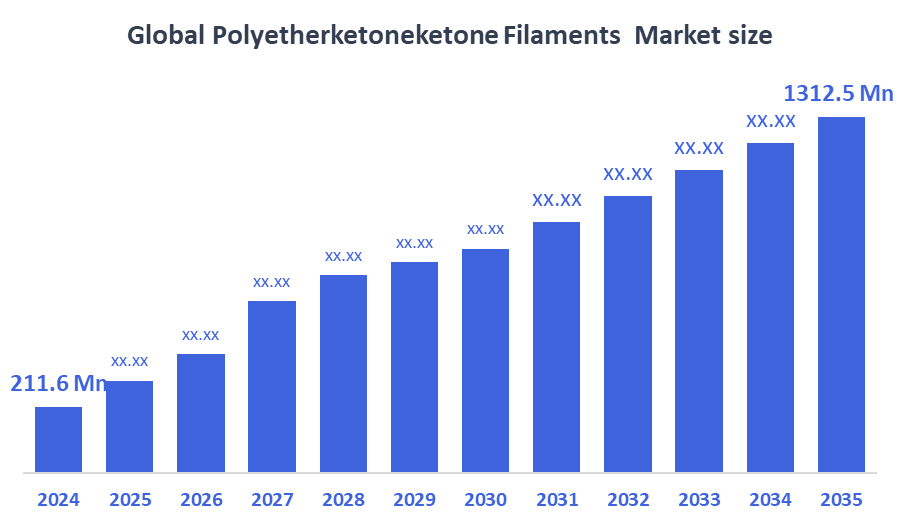

According to Decision Advisor, The Global Polyetherketoneketone Filaments Market Size is Expected to Grow from USD 211.6 Million in 2024 to USD 1312.5 Million by 2035, at a CAGR of 18.05% during the forecast period 2025-2035. Strong demand is being driven by the need for high?performance 3D printing materials with superior thermal, mechanical, and chemical resistance for mission?critical applications in aerospace, medical, automotive, and industrial sectors.

Key Market Insights

- North America accounted for the largest market share in 2024.

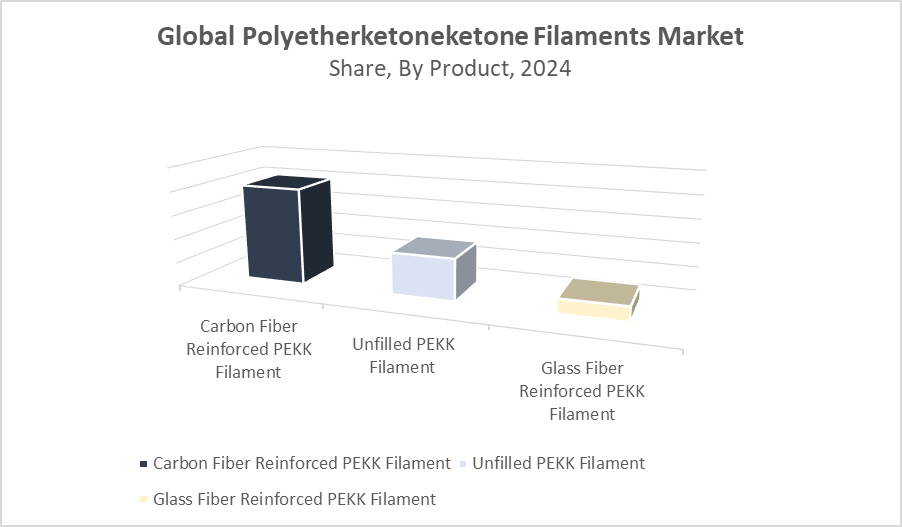

- The carbon fiber reinforced PEKK filament segment recorded the largest revenue share among product types in 2024 and is projected to grow at the fastest CAGR.

- Among applications, the Aerospace segment holds the largest share in 2024.

- The Automotive application is expected to have the fastest growth rate through the forecast period.

- Asia Pacific is forecasted to witness the fastest regional growth rate over the forecast period.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 211.6 Million

- 2035 Projected Market Size: USD 1312.5 Million

- CAGR (2025-2035): 18.05%

- North America: Largest market in 2024

- Asia Pacific: Fastest growing market

Polyetherketoneketone Filaments Market

The Polyetherketoneketone filaments market centres on the production and use of high?performance, high?temperature, chemically resistant thermoplastic filament materials, used primarily in additive manufacturing / 3D printing. These filaments (reinforced or unfilled) are used for parts that demand strength, durability, lightweight construction, and resistance under high heat and harsh environments. Growing adoption of 3D printing beyond prototyping into more functional and end?use applications is pushing demand. COVID?19 caused supply chain challenges and delays for specialized polymer raw materials, but demand recovered quickly as industries such as aerospace, medical, and automotive refocused on resilient, lightweight, and high?performance materials. Tariff and trade war impacts are seen in costs of reinforcement fibers (carbon fiber, glass fiber) and shipment of specialty polymers.

Polyetherketoneketone Filaments Market Trends

- Rising preference for carbon fiber reinforced PEKK due to enhanced stiffness, strength?to?weight ratio, and better thermal performance.

- Unfilled PEKK remains important for applications where pure polymer properties (chemical resistance, biocompatibility, clean surface finish) are critical.

- Growing interest in glass fiber reinforced filaments as cost?balanced alternatives between pure and carbon reinforced variants.

- Increasing penetration of 3D printing in end?use parts in aerospace, medical implants, and automotive components.

- Focus on process improvements: better filament quality, reduced warping, higher consistency, and enhanced printing reliability.

Polyetherketoneketone Filaments Market Dynamics

Driving Factors: Rising demand for high-performance materials across aerospace

The Polyetherketoneketone filaments market is being driven by rising demand for high-performance materials across aerospace, automotive, and medical sectors. These industries require components that can withstand extreme temperatures, mechanical stress, and chemical exposure. Additionally, the growth of additive manufacturing is fueling the adoption of PEKK filaments due to their lightweight properties and exceptional durability. Increasing focus on fuel efficiency and emissions reduction, especially in aerospace and EVs, further boosts the need for strong, heat-resistant, and lightweight 3D printing materials like PEKK.

Restrain Factors: Processing PEKK requires high-temperature equipment

High material and production costs remain major restraints for the Polyetherketoneketone filaments market. PEKK resin is significantly more expensive than standard polymers, and incorporating reinforcement fibers (like carbon or glass) adds to the cost. Moreover, processing PEKK requires high-temperature equipment, which increases operational expenses. These cost barriers limit broader adoption, especially in price-sensitive industries or developing regions. Regulatory approvals in aerospace and medical sectors also delay product entry, adding further complexity and cost for market participants.

Opportunity: Medical devices benefit from PEKK’s biocompatibility and sterilization resistance

There is substantial growth opportunity for PEKK filaments in electric vehicles, medical implants, and industrial components. As the demand for lightweight, high-strength, and chemically resistant parts increases, PEKK is well-positioned to replace metal and less durable polymers. Medical devices benefit from PEKK’s biocompatibility and sterilization resistance, while EVs and aerospace sectors need it for performance and efficiency. Additionally, emerging economies in Asia Pacific are investing in advanced manufacturing, creating new markets for high-performance 3D printing filaments like PEKK.

Challenges: High energy consumption during production

The Polyetherketoneketone filaments market faces challenges related to processing complexity, supply chain limitations, and regulatory hurdles. Producing consistent, high-quality filaments with uniform fiber distribution is technically demanding. Limited availability of raw materials like PEKK resin and carbon fiber can disrupt supply chains and affect pricing. Furthermore, applications in aerospace and medical fields require strict certifications, increasing time to market. High energy consumption during production and the need for specialized 3D printers also pose operational and adoption challenges.

Global Polyetherketoneketone Filaments Market Ecosystem Analysis

The global Polyetherketoneketone filaments market ecosystem includes raw material suppliers, filament manufacturers, 3D printer OEMs, end-users, and regulatory bodies. Raw resin and fiber suppliers affect cost and quality. Filament producers ensure printability and reinforcement integration. High-temperature 3D printers are essential for processing PEKK. End-users in aerospace, automotive, and medical industries drive demand, requiring certified, high-performance materials. Regulatory standards shape product acceptance, while innovation and hardware-material compatibility drive market growth. The ecosystem thrives on quality, compliance, and advanced manufacturing capabilities.

Global Polyetherketoneketone Filaments Market, By Product

Carbon fiber reinforced PEEK filament segment held the largest revenue share of approximately 55% in 2024. It combines the inherent durability, thermal resistance, and chemical stability of PEKK with the stiffness and strength of carbon fiber. Due to these properties, it is highly demanded in aerospace, automotive, and industrial structural applications where lightweight materials with high strength are critical for enhancing performance and efficiency.

Unfilled PEKK filament accounting for around 30% of the market share in 2024, unfilled PEKK filament is widely used in medical devices, electronics housings, and chemical processing parts. Its key advantages include excellent chemical stability, purity, biocompatibility, and a smooth surface finish. These attributes are more important than mechanical reinforcement in applications that require stringent safety and performance standards.

Global Polyetherketoneketone Filaments Market, By Application

The aerospace segment was the largest application in 2024, holding the highest revenue share. PEKK filaments are extensively used for lightweight structural components, brackets, ducts, and interior panels in aircraft. The segment demands materials with exceptional thermal, chemical, and mechanical performance to withstand harsh operating conditions while reducing weight for improved fuel efficiency and durability.

The automotive segment is the fastest growing application area. PEKK filaments are increasingly used in electric vehicles (EVs), propulsion and battery components, under-hood parts, as well as structural and aesthetic elements. Their lightweight and high-strength properties contribute to vehicle efficiency, performance, and design innovation, driving strong market growth in this sector.

North America was the largest market for Polyetherketoneketone filaments in 2024.

This leadership is driven by the presence of well-established aerospace, automotive, and medical industries that demand high-performance materials. The region benefits from advanced manufacturing infrastructure, significant R&D investments, and supportive government policies promoting innovation and sustainability. These factors combine to create strong market demand and high revenue generation.

Asia Pacific emerged as the fastest-growing Polyetherketoneketone market in 2024.

Rapid industrialization, expanding manufacturing capabilities, and increasing adoption of advanced materials in aerospace, automotive, and electronics sectors fuel this growth. Additionally, supportive government initiatives, growing urbanization, and rising investments in infrastructure and technology drive accelerated market expansion in the region.

WORLDWIDE TOP KEY PLAYERS IN THE POLYETHERKETONEKETONE FILAMENTS MARKET INCLUDE

- Solvay

- Ensinger

- 3DXTech

- ARMOR Group

- IEMAI 3D

- Shandong Kaisheng New Materials Co., Ltd.

- Lehmann & Voss

- INTAMSYS Technology Co. Ltd.

- DELRAY Systems

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the Polyetherketoneketone filaments market based on the below-mentioned segments:

Global Polyetherketoneketone Filaments Market, By Product

- Carbon Fiber Reinforced PEKK Filament

- Unfilled PEKK Filament

- Glass Fiber Reinforced PEKK Filament

Global Polyetherketoneketone Filaments Market, By Application

- Aerospace

- Automotive

- Medical Devices

- Industrial Components

Global Polyetherketoneketone Filaments Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

FAQs

Q: What are the main drivers of growth in the PEKK Filaments Market?

A: Key drivers include rising demand for high-performance 3D printing materials in aerospace, automotive, and medical sectors, as well as the shift toward lightweight and durable components.

Q: What challenges are limiting the adoption of PEKK filaments?

A: High material and processing costs, supply chain limitations, regulatory barriers, and the need for high-temperature 3D printing equipment are key restraints.

Q: What are the latest trends in the Polyetherketoneketone Filaments Market?

A: Trends include increasing use of carbon fiber reinforced variants, focus on filament quality and consistency, growing adoption in end-use parts, and rising interest in glass fiber-reinforced PEKK as a cost-effective alternative.

Q: What are the top investment opportunities in the PEKK Filaments Market?

A: Opportunities include applications in EV components, medical implants, and industrial parts, as well as growth in emerging markets and strategic collaborations for advanced additive manufacturing solutions.

Q: Which industries are adopting PEKK filaments most extensively?

A: Aerospace, automotive, medical devices, and industrial manufacturing are the leading industries adopting PEKK filaments for their high-performance requirements.

Q: How did COVID-19 and trade tensions affect the PEKK Filaments Market?

A: The market faced initial supply chain disruptions, especially for specialty polymers and reinforcement fibers, but recovered due to renewed demand in critical sectors and reshoring of production.

Q: What is the long-term outlook (2025–2035) for the PEKK Filaments Market?

A: The market is expected to experience strong and sustained growth through 2035, fueled by innovation, material performance demand, and expanding applications in advanced manufacturing.

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Global |

| Pages | 236 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Oct 2025 |

| Access | Download from this page |