Global Tantalum Carbide Coatings for Graphite Market

Global Tantalum Carbide Coatings for Graphite Market Size, Share, and COVID-19 Impact Analysis, Impact of Tariff and Trade War Analysis, By Process (Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)), By Substrate Form (Blocks, Fixtures, and Crucibles), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Report Overview

Table of Contents

Tantalum Carbide Coatings for Graphite Market Size Summary, Size & Emerging Trends

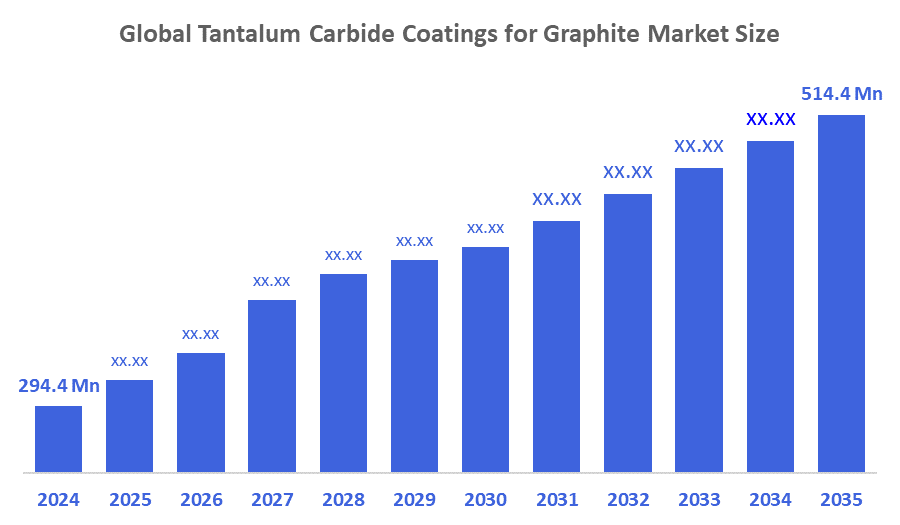

According to Decision Advisor, the Global Tantalum Carbide Coatings for Graphite Market Size is expected to Grow from USD 294.4 Million in 2024 to USD 514.4 Million by 2035, at a CAGR of 5.2% during the forecast period 2025-2035. The increasing demand for enhanced thermal and chemical resistance in graphite components across industries such as aerospace, metallurgy, and electronics is driving the market growth.

Key Market Insights

- Asia Pacific is expected to dominate the tantalum carbide coatings market due to rapid industrialization and increasing adoption in electronics manufacturing.

- The chemical vapor deposition (CVD) process segment holds the largest revenue share due to its superior coating uniformity and adhesion.

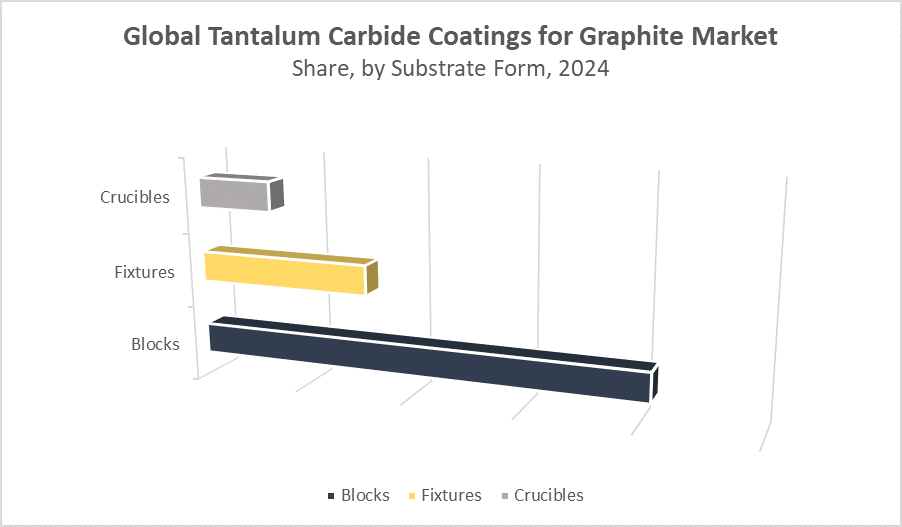

- Blocks substrate form accounts for the largest revenue share, attributed to its widespread use in high-temperature applications.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 294.4 Million

- 2035 Projected Market Size: USD 514.4 Million

- CAGR (2025-2035): 5.2%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Tantalum Carbide Coatings for Graphite Market

The tantalum carbide coatings for graphite market centers on applying protective coatings to graphite substrates to enhance durability, wear resistance, and corrosion resistance, particularly under extreme thermal and chemical conditions. These coatings are essential in applications ranging from aerospace components and metallurgical crucibles to semiconductor manufacturing fixtures. The high melting point and chemical inertness of tantalum carbide significantly improve graphite’s performance, enabling extended service life and operational efficiency. Industry adoption is propelled by rising demand for high-performance materials capable of withstanding aggressive environments, supported by government initiatives promoting advanced material technologies.

Tantalum Carbide Coatings for Graphite Market Trends

- Growing preference for Chemical Vapor Deposition (CVD) due to its precise control and uniform coatings.

- Increasing investment in PVD technologies to achieve cost-effective coating processes with reduced environmental impact.

- Strategic collaborations between coating technology providers and end-users to develop tailored solutions.

Tantalum Carbide Coatings for Graphite Market Dynamics

Driving Factors:

Applying tantalum carbide coatings significantly enhances thermal resistance

The tantalum carbide coatings market is primarily driven by the growing need for materials that can withstand extreme conditions. In aerospace, components often face very high temperatures and corrosive environments where uncoated graphite would degrade rapidly. Applying tantalum carbide coatings significantly enhances thermal resistance and chemical inertness, extending component lifespan and improving safety. Similarly, in metallurgy, coated crucibles and fixtures endure intense heat and reactive metals, demanding durable protection to prevent damage and contamination. Moreover, advancements in Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) technologies have improved coating quality, uniformity, and adhesion, while reducing manufacturing time and costs. This has expanded their applicability into electronics and semiconductor manufacturing, where precise and reliable coatings are crucial. The ongoing push for miniaturization and higher performance in these industries continuously fuels demand for superior coatings.

Restrain Factors:

Applying uniform coatings on intricate graphite geometries is technically challenging

Despite the promising applications, several factors limit market growth. Tantalum carbide itself is an expensive material, and the processes used to deposit it especially CVD and PVD are complex, requiring specialized equipment and controlled environments. These requirements translate into higher production costs compared to simpler coating materials. Additionally, applying uniform coatings on intricate graphite geometries is technically challenging, inconsistencies can lead to weak spots, reducing performance and causing premature failure. The niche expertise needed to optimize coating parameters further constrains scalability.

Opportunity:

Aerospace materials are also evolving towards lightweight

There is significant potential in developing hybrid coating techniques that combine the advantages of CVD and PVD to produce coatings with enhanced mechanical and thermal properties while optimizing cost and environmental impact. For example, applying a base layer via CVD for strong adhesion followed by a PVD topcoat for precise thickness control can yield superior results. Emerging industries, such as semiconductors and renewable energy (solar cells, batteries), are increasingly requiring coatings that protect critical components under harsh operational conditions, creating new demand pockets. Aerospace materials are also evolving towards lightweight, high-strength composites that benefit from tailored coatings. Furthermore, the global push toward sustainability and reducing carbon footprints drives innovation toward eco-friendly coating processes that minimize hazardous emissions and energy consumption. These trends open avenues for market expansion, especially for companies investing in R&D for greener technologies.

Challenges:

Environmental regulations governing emissions

The tantalum carbide coatings market faces multiple challenges that must be managed carefully. Raw material supply is vulnerable to geopolitical issues, export restrictions, and price volatility, causing uncertainty in procurement and budgeting. Additionally, environmental regulations governing emissions, chemical waste, and energy use in coating facilities are becoming increasingly stringent worldwide. Compliance requires significant investment in pollution control technologies and process modifications, which can slow adoption and increase costs. Another challenge is the shortage of skilled personnel trained in advanced coating technologies, especially in developing countries where demand is growing but technical expertise is limited. This labor gap and technological barriers hinder the establishment of new production facilities in these regions.

Global Tantalum Carbide Coatings for Graphite Market Ecosystem Analysis

The ecosystem includes device manufacturers, material suppliers, distributors, and end-use healthcare providers. Key manufacturers like Stryker, DePuy Synthes, Zimmer Biomet, and Medtronic play critical roles in R&D and commercialization. Raw material suppliers provide high-grade titanium and bioresorbable polymers. Hospitals and surgical centers drive the demand. Regulatory bodies such as the FDA and EMA influence market entry and device adoption. Strategic collaborations and global distribution networks are essential for market penetration and sustainability.

Global Tantalum Carbide Coatings for Graphite Market, By Process

The chemical vapor deposition (CVD) segment holds the dominant market share, accounting for approximately 70% of the tantalum carbide coatings market. This dominance is attributed to CVD’s ability to produce highly uniform, dense, and strongly adherent coatings, which are critical in demanding sectors like aerospace and semiconductors. The precise control over coating thickness and composition allows manufacturers to meet stringent performance and reliability standards. Due to these superior qualities, CVD remains the preferred choice for high-performance applications where coating integrity and durability are paramount.

The physical vapor deposition (PVD) segment commands a smaller yet rapidly growing share, approximately 35% of the market. PVD is gaining traction as a more cost-effective and environmentally friendly coating method. It is particularly suitable for applications where coating complexity and thickness control are less critical, such as coatings on fixtures and crucibles used in industrial metal processing. The rising emphasis on sustainable manufacturing practices further supports PVD’s growth, making it an increasingly popular alternative, especially in regions with strict environmental regulations.

Global Tantalum Carbide Coatings for Graphite Market, By Substrate Form

The blocks segment accounts for the largest revenue share in the tantalum carbide coatings market, representing approximately 60% of the total market. This dominance is due to their widespread use in high-temperature crucibles and other critical components that require enhanced durability and thermal stability. Blocks coated with tantalum carbide ensure longer service life and improved performance in harsh metallurgical and aerospace environments, making them indispensable in these applications.

The fixtures segment holds a significant market share of around 30%, serving as crucial components in metallurgical and electronics manufacturing processes. Fixtures coated with tantalum carbide provide precision, corrosion resistance, and mechanical strength, which are essential for maintaining quality and efficiency in production. Their role in complex manufacturing setups continues to drive steady demand, especially as industries adopt advanced coating technologies.

The Asia Pacific region is projected to hold the largest market share in the tantalum carbide coatings for graphite market, estimated at around 45% during the forecast period.

This leadership is driven by the booming electronics manufacturing hubs in China, India, Japan, and Southeast Asia. Rapid industrialization, expanding aerospace activities, and substantial infrastructure development contribute to strong demand for high-performance coatings. The region’s increasing focus on advanced materials and manufacturing technologies further cements its dominant position in the market.

North America is expected to be the fastest-growing regional market, with a CAGR surpassing other regions and capturing approximately 25% of the market share by the end of the forecast period.

This growth is fueled by major aerospace investments and rising adoption of cutting-edge coating technologies. The presence of leading manufacturers and research institutions accelerates innovation and supports robust market expansion across the U.S. and Canada.

WORLDWIDE TOP KEY PLAYERS IN THE TANTALUM CARBIDE COATINGS FOR GRAPHITE MARKET INCLUDE

- H.C. Starck

- Kennametal Inc.

- Plansee SE

- Oerlikon Balzers

- Sandvik AB

- Advanced Coating Technologies

- Denssolutions

- Others

Product Launches in Tantalum Carbide Coatings for Graphite Market

- In January 2024, Plansee SE introduced an advanced Chemical Vapor Deposition (CVD) coating system engineered to deliver improved coating uniformity and higher production throughput. This innovation specifically targets the demanding aerospace and semiconductor industries, where precision and consistency are critical. The new system aims to enhance coating quality while boosting manufacturing efficiency, addressing the sector’s need for reliable, high-performance tantalum carbide coatings.

- In July 2024, Oerlikon Balzers launched a groundbreaking Physical Vapor Deposition (PVD) coating solution focused on environmental sustainability. This new eco-friendly technology significantly reduces process emissions and lowers energy consumption during coating applications. By aligning with global environmental regulations and sustainability goals, this PVD solution supports greener manufacturing practices without compromising coating performance, making it attractive for industrial users prioritizing eco-conscious production.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the tantalum carbide coatings for graphite market based on the below-mentioned segments:

Global Tantalum Carbide Coatings for Graphite Market, By Process

- Chemical Vapor Deposition (CVD)

- Physical Vapor Deposition (PVD)

Global Tantalum Carbide Coatings for Graphite Market, By Substrate Form

- Blocks

- Fixtures

- Crucibles

Global Tantalum Carbide Coatings for Graphite Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Global |

| Pages | 212 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Oct 2025 |

| Access | Download from this page |