Global Twin Screw Extruders Market

Global Twin Screw Extruders Market Size, Share, and COVID-19 Impact Analysis, By Product (Co-rotating Twin Screw Extruders, Counter-rotating Twin Screw Extruders), By End-use (Plastic & Polymer Processing, Food Processing, Pharmaceutical, Chemical, Rubber, Other), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Report Overview

Table of Contents

Twin Screw Extruders Market Size Summary

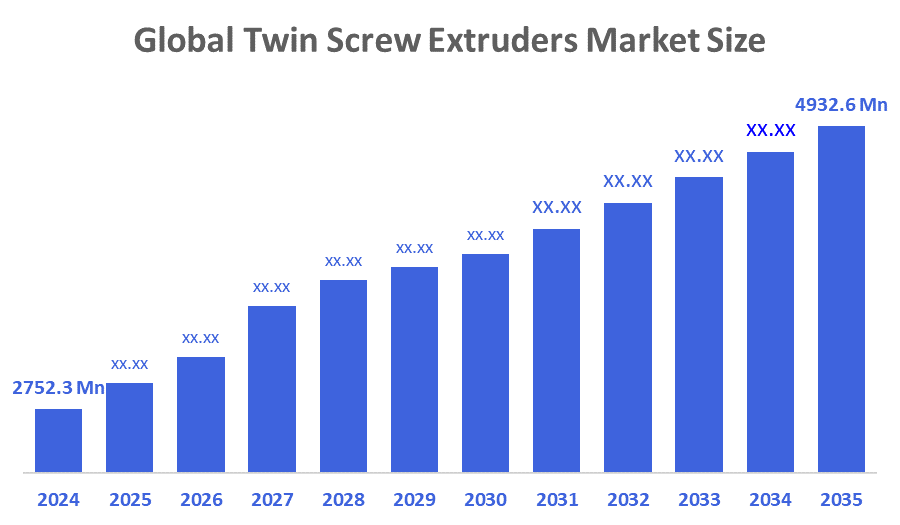

The Global Twin Screw Extruders Market Size Was Estimated at USD 2752.3 Million in 2024 and is Projected to Reach USD 4932.6 Million by 2035, Growing at a CAGR of 5.45% from 2025 to 2035. The market for twin screw extruders is expanding as a result of growing demand for effective, adaptable processing in the food, pharmaceutical, and plastics industries; increased automation; improved mixing capabilities; and expanding use in compounding and recycling applications, which promote improved product quality and operational efficiency.

Key Regional and Segment-Wise Insights

- In 2024, the Asia Pacific held the largest revenue share of over 39.2% and dominated the market globally.

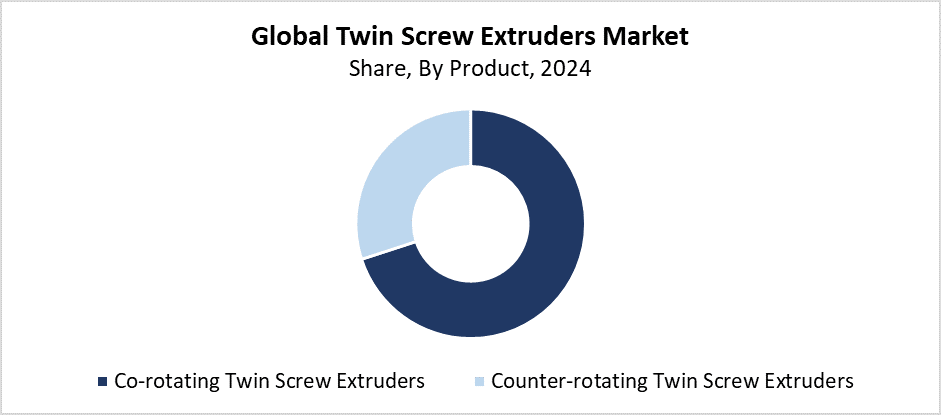

- In 2024, the co-rotating twin screw extruders segment had the highest market share by product, accounting for 70.5%.

- In 2024, the plastic and polymer processing segment had the biggest market share by end use, accounting for 62.3%.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 2752.3 Million

- 2035 Projected Market Size: USD 4932.6 Million

- CAGR (2025-2035): 5.45%

- Asia Pacific: Largest market in 2024

Twin Screw Extruders market manufactures and operates processing equipment for polymers and food, chemicals, and pharmaceutical products that use dual interlocking screws. These extruders deliver enhanced mixing capabilities, temperature regulation, and processing adaptability when compared with single screw extruders. The market expansion occurs due to three primary factors, which include rising premium plastic product demand and sophisticated food processing adoption, and the expanding pharmaceutical industry. The market for twin screw extruders used to compound recycled polymers grows because of rising recycling initiatives and customer interest in sustainable products. Industrial sectors drive market growth through their focus on enhanced production efficiency, together with improved product consistency.

The industry of Twin Screw Extruders experiences major changes due to technological progress. Energy-efficient motors together with enhanced control systems and modular screw designs have led to decreased energy use while operators achieve better precision in their operations. The combination of automation with digital systems enables real-time monitoring, which produces better process control and increased output. The utilization of twin screw extruders in recycling and bio-based material processing receives support from government initiatives that promote waste reduction and sustainable manufacturing practices. The market growth and technological progression accelerate because of legal frameworks and financial support for industrial innovation across North America, Europe, and the Asia-Pacific territories.

Product Insights

The co-rotating twin screw extruders segment led the twin screw extruders market with the largest revenue share of 70.5% in 2024. The market dominance of co-rotating twin screw extruders stems from their excellent self-cleaning characteristics and high throughput, combined with superior mixing performance that suits complex compounding and processing operations. The industries of polymers and food, together with chemicals and pharmaceuticals, utilize co-rotating twin screw extruders for their advanced dispersive and distributive mixing functions and enhanced temperature management. Co-rotating twin screw extruders gain flexibility in processing different materials, especially recycled polymers, because of rising sustainability requirements. The market leadership position of co-rotating twin screw extruders has been reinforced through these advantages.

The counter-rotating twin screw extruders segment is expected to grow at the fastest CAGR throughout the forecasted period. The segment experiences segment growth through its high shearing power and processing capabilities for viscous materials, which enable its usage in food processing and pharmaceutical and chemical synthesis applications. Certain formulations benefit from the enhanced torque transfer capabilities of counter-rotating extruders, along with better material residence time control, which leads to increased processing efficiency. The market for counter-rotating twin screw extruders will expand because of increasing demand for exact processing methods, especially across developing nations. The rapid expansion of this segment results from ongoing technological developments as well as increasing recognition of its benefits for specialized applications.

End-use Insights

The plastic and polymer processing segment dominated the Twin Screw Extruders market by generating 62.3% of total revenue in 2024. Twin screw extruders dominate the market because they perform critical tasks in processing various plastic and polymer materials through compounding and blending, and other processing operations. The equipment excels in mixing operations while delivering efficient heat transfer and complex formulation processing capabilities, which make it crucial for manufacturing top-quality plastic products serving packaging, automotive, construction, and consumer goods applications. Lightweight, durable, sustainable polymer materials, along with increasing recycling activities, drive the segment's growth to new heights. The plastic and polymer industry maintains its market dominance in twin screw extruders through its ongoing material development initiatives.

Throughout the forecast period, the pharmaceutical segment of the Twin Screw Extruders market is anticipated to grow at the fastest CAGR. The fast growth of twin screw extrusion technology for advanced medicine formulation, including controlled-release tablets, pellets, and nanoparticles, leads to this rapid expansion. The precise temperature control, along with effective mixing and scalability features of twin screw extruders, makes them ideal for pharmaceutical operations that need high quality and consistency. The rising demand for biologics and personalized treatment, together with continuous production methods, drives market growth. Regulatory support, along with increasing pharmaceutical research and development investment, accelerates this segment's expansion. The pharmaceutical industry relies more heavily on twin screw extruders because it moves toward sustainable production methods with improved effectiveness.

Regional Insights

The market for twin screw extruders in North America is anticipated to grow at a significant CAGR during the forecast period because of the increasing needs of key sectors such as food processing, along with pharmaceuticals and plastics. Market growth occurs because of the region's focus on advanced manufacturing methods and the escalating adoption of sustainable and energy-efficient processing machinery. The pharmaceutical sector utilizes twin screw extrusion increasingly for precise and scalable manufacturing because of growing investments in continuous drug development and manufacturing. The plastics industry experiences growth because of rising plastic recycling trends and the need for superior polymer processing solutions. The North American market benefits from government programs that support both industrial automation and technical innovation for its expansion.

Europe Twin Screw Extruders Market Trends

The European market for twin screw extruders is growing significantly because of the continent's strong industrial environment and manufacturing technology advancements. The reliability, adaptability, and efficiency of twin screw extruders make them increasingly popular in vital industries, including food processing, polymers, and medicines. The use of twin screw extruders for recycling applications, mainly plastics and polymers, receives a boost from sustainable production initiatives and circular economy principles. The pharmaceutical industry in Europe, which follows strict regulations, has adopted continuous manufacturing, which boosts demand for this technology. The market strengthens through technological advances and government innovation support, as well as energy-efficient equipment promotion. The expanding regional market receives its main leadership from nations that include France, Italy, and Germany.

Asia Pacific Twin Screw Extruders Market Trends

The Twin Screw Extruders market in the Asia Pacific held the largest revenue share of 39.2% and led the market globally in 2024. The manufacturing infrastructure of the Asia Pacific, particularly China, India, Japan, and South Korea, drives this regional leadership. The market experiences expansion because of quick industrial development alongside the increasing need for plastic and polymer products, along with the rising food processing and pharmaceutical sectors. Emerging nations have witnessed growing interest in twin screw extruders because they offer affordable and high-performance machinery solutions. The region benefits from increased investments directed toward sustainable production technologies and recycling processes. The Asia Pacific region continues to lead the worldwide twin screw extruders market because it houses major manufacturers who focus on production efficiency along with innovation.

Key Twin Screw Extruders Companies:

The following are the leading companies in the twin screw extruders market. These companies collectively hold the largest market share and dictate industry trends.

- Coperion GmbH

- WENGER MANUFACTURING

- ICMA San Giorgio

- Leistritz Extrusionstechnik GmbH

- Bausano S.p.A

- Bühler Group

- Baker Perkins

- ICMA San Giorgio

- Thermo Fisher Scientific Inc.

- Milacron

- KraussMaffei Group

- Battenfeld-Cincinnati

- Xtrutech Ltd.

- Others

Recent Developments

- In July 2025, Coperion launched C-BEYOND, a digital platform, at colorplasticchemie to allow for real-time ZSK extruder monitoring. To enhance maintenance and planning, the system monitors pollutants, energy consumption, and performance. Additionally, it optimizes output and minimizes downtime. It will be presented by Coperion in Düsseldorf at K 2025.

- In January 2025, Useon collaborated with the National Fund for Innovation to advance its development of machines. As part of the agreement, new shares will be issued to enable the production of modern extruders and pelletizers. The goal of this action is to improve Useon's industrial capacity. It is an important stage in expanding growth and innovation.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decisions Advisors has segmented the twin screw extruders market based on the below-mentioned segments:

Global Twin Screw Extruders Market, By Product

- Co-rotating Twin Screw Extruders

- Counter-rotating Twin Screw Extruders

Global Twin Screw Extruders Market, By End Use

- Plastic & Polymer Processing

- Food Processing

- Pharmaceutical

- Chemical

- Rubber

- Other

Global Twin Screw Extruders Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Check Licence

Choose the plan that fits you best: Single User, Multi-User, or Enterprise solutions tailored for your needs.

We Have You Covered

- 24/7 Analyst Support

- Clients Across the Globe

- Tailored Insights

- Technology Tracking

- Competitive Intelligence

- Custom Research

- Syndicated Market Studies

- Market Overview

- Market Segmentation

- Growth Drivers

- Market Opportunities

- Regulatory Insights

- Innovation & Sustainability

Report Details

| Scope | Global |

| Pages | 187 |

| Delivery | PDF & Excel via Email |

| Language | English |

| Release | Oct 2025 |

| Access | Download from this page |